Introduction to Microcontrollers

Introduction to Microcontrollers

The purpose of this blog post is

to give readers an overview of working with Microcontrollers and successfully

implementing them in projects. There are numerous information on Microcontrollers

available out there but very few give a big picture of the implication of

building a project around them from beginning to end for people who have never

used them before.

What are Microcontrollers?

This is the first questions that

came to my mind when I first started to get involved with Microcontrollers,

what is a Microcontroller actually? In simple terms a Microcontroller is an

electronic device which is used to provide control signals to one or more

targets devices. The control signals can be used to do simple task such as

switch on a led, a relay or it can be a more complicated form of control signal

such as a serial protocol signal used to send data through a USB port for

instance.

In order to send the control

signals the Microcontroller has the ability to read input(directly or through

specialized devices), process them if required and in certain circumstances use

specialized internal/ external devices to generate the control signals.

To achieve the ability of

generating control signals, a set of instructions need to be programmed into

the Microcontroller.

A bit more on

control signals

Now some practical examples of

what you can do with Microcontrollers and their ability to generate control

signals(Not exhaustive):

Control

Signal

|

What can

you do with them?

|

Side Note

|

Power control(PWM)

|

Motor Control for robots and drones

|

External Motor Driver devices required

|

Power inverters(12V DC to 110/220V AC)

|

External power drivers required

|

|

Sound generation

|

Not hifi grade but usable for audible alerts

|

|

Audio applications

|

Send signals to specialized IC's to control

volume, tone or build a 5.1 or 7.1

|

Additional

external specialized ic required

|

Control DSPs(Digital signal processors)

|

Additional

External DSP device required

|

|

Digitally controlled equalizer

|

Additional

Digitally controlled equalizer ic required

|

|

FM tuner

|

Additional Digitally controlled FM receiver ic

required

|

|

Spectrum analyzer

|

Requires a powerful Microcontroller

|

|

FAT file system MP3 player(SD card, USB drive or

Parallel IDE hard disk)

|

Might require external decoder ic or decoding

done internally on Microcontroller. Use of proper external DAC recommended.

FAT library required. For usb drive USB host grade microcontroller required

|

|

Instrumentation

|

Function generator

|

Additional DDS ic or specialized function

generator ic required

|

PC based or standalone Oscilloscope

|

A very ambitious one but feasible with proper

external devices

|

|

PC based or stand alone logic analyzer

|

Another ambitious one but feasible with proper

external devices

|

|

Digitally controlled bench Power supply

|

Good quality external DAC required on top of

external power electronics

|

|

Data loggers to pc or FAT based storage

|

||

PCB building

|

PCB UV exposure timers

|

|

PCB etch temperature controllers

|

Use of PID logic recommended

|

|

SMD soldering oven temperature control

|

Use of PID logic recommended

|

|

Infrared Remote control

|

Receive or transmit infrared signals

|

Some Microcontrollers feature built in infrared

modules

|

What you see on the above list

are some examples of what can be done with Microcontrollers. The areas of

applications are actually wider than that. In commercial applications Microcontrollers

find their application in anywhere from consumer electronics to industrial

grade applications.

Working with Microcontrollers

let's get stated

Great now that you've had an idea

of how far a Microcontroller can be used let's go further on what we need to

put them to use.

Below is what you will need to

work with a Microcontroller:

1) The Microcontroller IC itself:

But shouldn't I consider a development board

first? That's a tricky one but let me explain. Normally whenever you are

building a Microcontroller based project you have to choose a Microcontroller

IC first. The reason being that the Microcontroller IC you will choose will be

the one sitting on your final circuit board with the other devices it will

control. Unless you are buying a development board to do a single one off

project I would highly recommend finding

the IC first. Below are some of the Microcontroller ICs that I use.

The next question that comes in

is how to choose this Microcontroller IC? First and foremost consider the

following:

i) What is/are the target devices

to be controlled?

ii) Is the use of specialized in

built modules required?

iii) How big is your program and is there enough Flash Memory on the device to hold

it?(More on this in simulation later)

iv) Are signal speeds/timing

extremely critical and can a Microcontroller handle it? In certain

circumstances you might need to revert to the use of CPLDs or FPGAs for

directly handling the signals with a Microcontroller. An extreme case is when

you might be building an oscilloscope or a memory controller. In those extreme

circumstances the Microcontroller serves the purpose of only sending control

signals to the CPLDs/FPGAs but not direct control of the target device itself.

v) What manufacturers build the Microcontroller

you have chosen and do they have microcontrollers that fall within you specs?

vi) Do you have access to the

selected Microcontroller support documents such as datasheet and the like?

vii) Last but not least is the Microcontroller(s)

you have chosen already available from your preferred online seller or local

seller? Is it in production or phased out? Is the price of the Microcontroller

within your budget or is it unaffordable?

As a simple guide my approach is

once I have decided on points i) to vi) above I go and look for the Microcontroller

online. In case it is not available (and will often be for newly launched

devices), I iterate back until I have reached a viable solution.

As you work with these devices,

you will get more familiar with certain brands and will tend to stick to them.

2) The development environment and the programming language

If you have settled with you Microcontroller

choice then comes the need to program it. There are two set of tools that are

needed to write code for a Microcontroller:

I) A development environment

The development environment is

where code is written. Most code written for Microcontrollers use C/C++ language. Some Microcontroller provide

a free development environment. you also have third party vendors that provide

a development environment for free or paid. How you feel at ease with the

development environment is up to you but you can go around downloading some and

give it a try

II) A compiler

The compiler is the program that

will take the code you have written and convert it into a form that's usable by

your Microcontroller. Some development environment feature built in full fledge

compilers for free, provide a time or code size limited compiler for free but a

paid version is required for full use. From my experience unless you are

building an extreme project, a code size limited version can be used for most

projects. The table below at time of writing gives a good idea.

Platform/Manufacturer

|

IDE

|

Compiler

|

Microchip

|

Free

|

XC compilers-code limited free, full version paid

|

Arduino

|

Free

|

Free

|

IAR embedded workbench

|

*Free

|

Code or time limited, full version paid

|

Mikroelectronica

|

*Free

|

Paid

|

ST

|

Free

|

Paid

|

Coocox

|

Free

|

*Free uses GCC compiler

|

TI

|

Third party both free and paid

|

FREE GCC others paid

|

Keil

|

*Paid

|

Paid

|

ATMEL

|

Free

|

*Free uses GCC compiler

|

An important note here, the above

is only provided as a rough guide based on information freely available on the

net. This being said, as you see the world is not as simple as it seems but the

choice is yours. In case you are embarking on a commercial project my advice is

to go with the paid solutions as they feature more support and less time to

market. In case you are a DIYer s a limited or fee version can do the job. You

will also notice there is more paid in the compiler column than the IDE one.

The reason behind being that it's the compiler that actually does the delicate

job or converting your source code and also optimizing it for use on your Microcontroller.

3) The programmer

If you have reached this step it

means your Microcontroller is settled and thankfully your development

environment and compiler as well. Now once you have finished writing your code,

how do you get it into your Microcontroller? Well you need a programmer. What's

the programmer? It's simply a hardware that you can purchase that connects to

your pc through a port. Most often these days most programmers connect through

a USB port. The programmer next connects to your Microcontroller through

dedicated pins. From your development environment or an additional software you

will be able to press a button that will send the compiled code to you Microcontroller. Below are some examples of programmers:

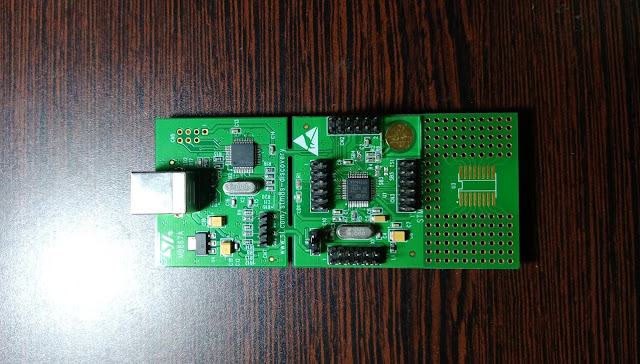

As you can notice both devices

feature a USB port and a special connector for the Microcontroller IC. There

are some manufacturer specific programmers, clone programmers and universal

ones.

4) The development board

At last we get there. The

development board is actually a printed circuited board that contains your chosen

microcontroller. The development board can be used for placing connecting wires

going to other add on modules or shields as they are called. The advantage of a

development board is that the code can be sent to the microcontroller with a

programmer without having to solder or setup basic connections. It also serves

as a first level prototype that can give an idea of how the project is turning

out. But as you get my point about the microcontroller IC I stated above this

is just a prototype not your final circuit.

Development boards can be

purchased direct from manufacturers. Below are two of them. some development

boards also feature a build in programmer. Sometime the programmer is hard wired to the microcontroller

and cannot be used elsewhere sometimes they have jumpers that can be used to

turn them into a standalone programmer. some newer versions even have slots in the

board where the programmer board can be snapped off.

In case you feel that manufacturer

development boards are too expensive, an alternative is what I would call

"OEM development boards". You

can find these easily online at smaller prices. Just be careful of the build quality

sometimes the board costs the same price as a microcontroller and you might

have ICs that were sent off the QC test to land onto those boards, but they do

work well enough for prototyping.

In case you are feeling

adventurous you can build your own development board. It's a cheaper alternative

you will need to read the microcontroller datasheet to understand where power

goes, what pins need bypassing, where the crystal oscillator goes e.t.c. You

will also need a good PCB design software, proper power, signal and ground

plane routing as is the case usually when designing a PCB. don't let yourself

scared by SMD's they are just a package and a lot of people have been able to

successfully design their own development boards with them.

It is to note as well that there

as a lot of development packages available online that come with plenty of add

on boards or have devices prebuilt. These boards are a very nice option in case

you want to focus on learning all the aspect related to microcontrollers.

Finalizing your

project

Once you are done with testing

your code with your prototype its normally time to go for the final version. In

case you are happy and everything works as expected you can start designing the

final PCB. Actually in practice I have not been so lucky mostly in cases where

I was building something complex. There have always been two issues I ended up

facing most of the time:

i) Vibration, noise and stability

As I mentioned before, using

development boars might require the use of wires and sometimes breadboard to

connect to other devices. Very often it can be a headache as you are working

and probing the circuit. Wires move, get disconnected accidentally. You hit the

table and all the wires vibrate sending chaos to your circuit.

Another point is the signal

frequency used by microcontrollers. For certain projects I had signals running

as low as 2MHz to reaching nearly 100MHz and above. As such high frequencies

using connecting wires can cause EMI to flow around. Breadboard is another

source of high capacitance that in certain circumstances can be a pain to

control. A simple case, you want to flash a led, fine no issues. Try to control

a CPLD from a microcontroller and the CPLD in turn is controls a static RAM IC

with thresholds going above 100MHz to sample live signals is a nightmare with

connecting wires. Sometimes the connecting wires themselves can grow huge in

number.

ii) Power supply and stability

Very often most programmers can

supply the required voltages to a microcontroller. This can be set through the

development environment.

Some development boards also

feature power through a USB cable, external wall adapters or simply a proper

power supply.

I have always had the experience

of things working nicely at this stage. But when I would power the device from

outside i.e. with its target power source, it was a different picture. I had

automatic power resets or false reads. Properly designing and bypassing the

power supply that will power the final device is critical may it be battery

operated or mains operated.

I would also advise to have a

separate power line for the microcontroller and or additional digital devices.

Powering microcontrollers from analog supply is something I would not recommend

for signal integrity. Additionally make use of external regulators. Although

some microcontrollers feature built in voltage regulators don't solely rely on

them.

The cleaner your microcontroller

power supply is the cleaner your control signals will be. This being said

without going to extremes, like building a Class A amp grade power supply for a

microcontroller.

So how to get things cleaner with

signaling and power supply? Well the answer that helped me a lot was to first

design the PCB and then build a version of the PCB using project board with all

the connections properly soldered. An example is shown below:

The above is an example prototype

I used. After having tested all the aspects of the circuit with my development

board, I built a first version of this board to test everything. The microcontroller

is housed below the lcd display. A supply cap and regulator is visible bottom

left and the rest is next to the microcontroller pins below the lcd. It was

only through this circuit that I was able to stabilize my signals and corrected

power supply related problems. Some signal lines also had to be re routed.

Conclusion

I hope this article has been able

to help shed some light on microcontrollers and how you use them and the

process involved. I know some people get scared or run away from microcontrollers

because it seems like a beast to daunt in itself. The subject does require some

time and patience but you will surely get there. Microcontrollers are there and

improving everyday and being able to use such fantastic devices in your

projects can only mean you can build more interesting and ambitious projects.

Copyright © Introduction to Microcontrollers 2016. All Rights Reserved. Reproduction or usage of content prohibited unless approved and agreed by blog author.

Comments

Post a Comment